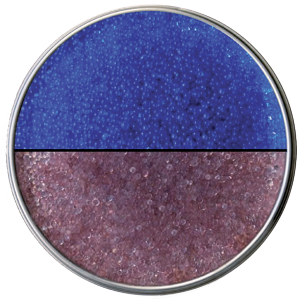

Description

Activated Alumina is a highly porous form of Aluminium Oxide with enhanced surface area. It is used for the adsorption of liquids and gases. One major application of Activated Alumina is as desiccant, either for the removal of bulk quantities of water or for drying of gases containing low concentration of water. The substances that can be treated with Activated Alumina are: Air, Ammonia, Argon, Carbon Dioxide, Furnace Gas, Hydrocarbon, Hydrogen, Nitrogen, Oxygen, Hydrogen Sulphide, Benzene, Gasoline, Lubricating Oil, Naptha, Vegetable Oil, Kerosene.

Special features

Oxide Activated Aluminas offer the following advantages:

•High water adsorption capacity

The highly developed surface and desired pore size distribution results in high water adsorption capacity. The benefits are extended operating life, smaller vessel design and longer cycle time.

•Low pressure drop

Low attrition loss and high crush strength minimises dusting in the bed and reduce pressure drops.

•Regeneration procedure

When Activated Alumina is loaded with water, it is regenerated by passing gas of lower relative humidity at a temperature around 200 °C.